Strategic Technical White Paper: Heavy-Duty Clutch Engineering and the Evolution of AMT in Emerging Markets

Introduction: The Critical Link in the Powertrain In the high-stakes logistics corridors of Algeria and the demanding mining terrains of Zambia and Tanzania, the clutch is the most abused yet most vital component of a heavy-duty truck. As the market transitions toward Automated Manual Transmissions (AMT), the role of the clutch has evolved from a simple wear item into a sophisticated mechatronic module. Understanding this evolution is the key to minimizing downtime and maximizing the Total Cost of Ownership (TCO) for modern fleets.

I. Anatomy of the Modern Clutch: Driving and Driven Components

According to foundational engineering standards (Ref 14.2), a clutch assembly is divided into two primary groups: the Driving Group and the Driven Group.

1. The Driving Group (Input Side)

This group is bolted directly to the engine flywheel and rotates at engine speed.

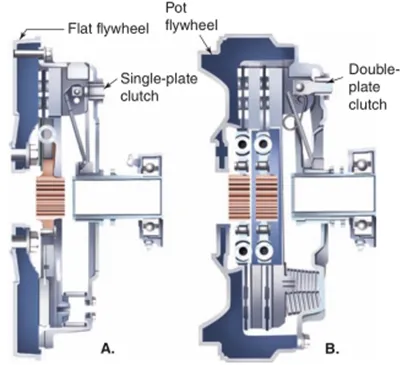

- The Flywheel: Although not technically part of the clutch, it is the foundation. It must be perfectly perpendicular to the crankshaft with a maximum runout of 0.005 inches (0.127 mm). In the extreme heat of the Algerian Sahara, any deviation leads to harmonic vibrations that can shatter the transmission input shaft.

- The Clutch Cover (Pressure Plate Assembly): For heavy-duty Class 8 trucks like the SHACMAN F3000, cast steel covers are used for superior heat dissipation compared to stamped steel versions used in light trucks.

- The Pressure Plate: This plate must slide freely on pins or lugs. When the pedal is released, spring pressure clamps the friction disc against the flywheel with enough linear force to prevent any slip under full load.

2. The Driven Group (Output Side)

This group transfers torque to the transmission input shaft.

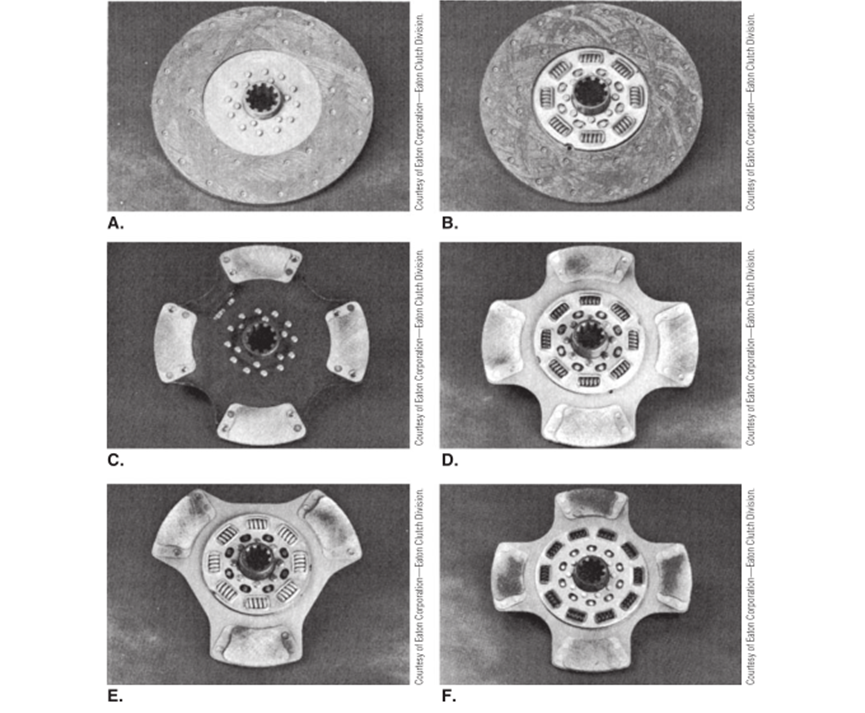

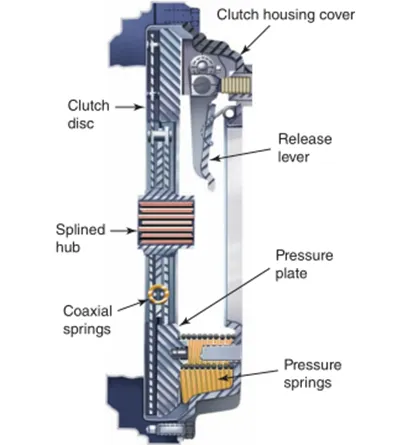

- Friction Disc Design: We differentiate between Rigid Discs (used in multi-disc setups for high surface area) and Damper Discs.

- The Role of Damping: High-torque engines (like those in the Hyundai HX340) produce massive torsional vibrations. Damper discs utilize coaxial springs in the hub to absorb these shocks, protecting the entire driveline from premature failure.

II. Advanced Spring Engineering: The Angle-Spring Advantage

One of the most critical components in a heavy-duty clutch is the spring system.

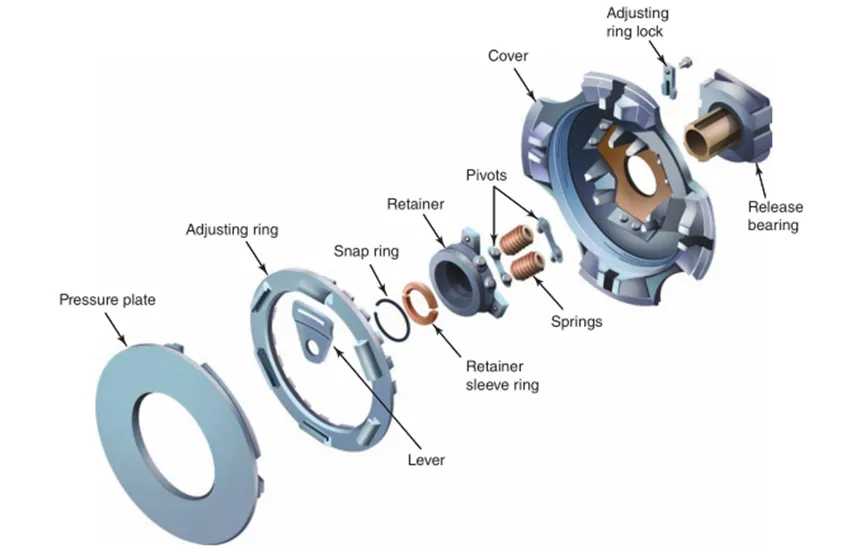

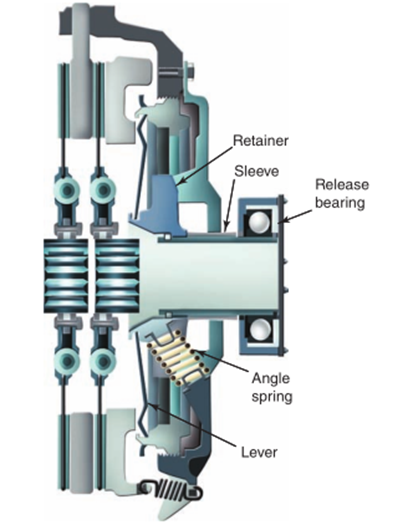

- Angle-Spring Design: Unlike traditional vertical springs, angle springs are placed at an angle between the cover and a retainer.

- Constant Loading: As the friction material wears down, a standard spring loses pressure. However, the Angle-Spring design maintains a constant pressure plate load (e.g., 3,200 lbs / 1,450 kg) throughout the entire life of the clutch.

- Effort Reduction: This geometry reduces clutch pedal effort by 50%, a vital factor for driver fatigue management on long hauls between Lusaka and Dar es Salaam.

III. Material Science: The Shift to Ceramic Facings

In the heavy-duty sector, the choice of friction material determines the “Survival Rate” of the truck.

- Organic Facings: Composed of glass and mineral wool. While smooth, they fail under the high-heat conditions typical of African infrastructure projects.

- Ceramic (Cermet) Facings: A mixture of ceramic, copper, and iron.

- Performance: Higher coefficient of friction and extreme heat resistance.

- The “Button” Design: Ceramic facings are riveted as “buttons” or “pads” (3, 4, or 6 buttons). This design allows for better cooling and debris shedding, which is essential in the dusty environments of Algerian construction sites.

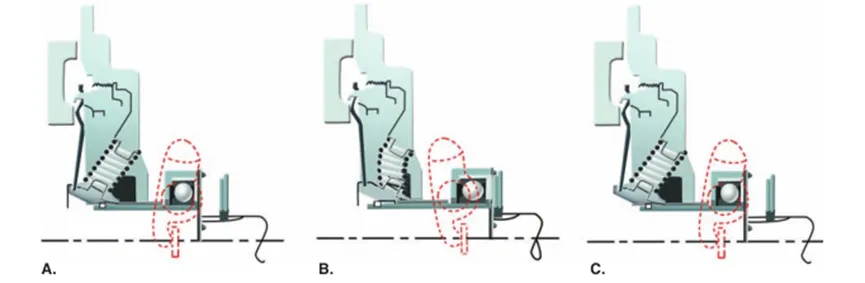

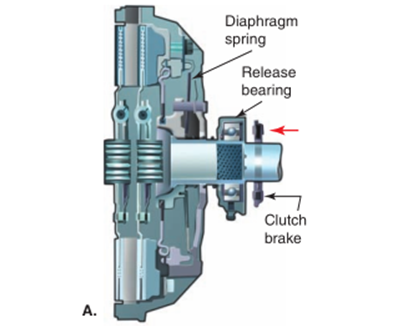

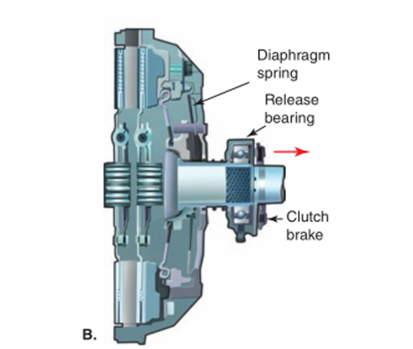

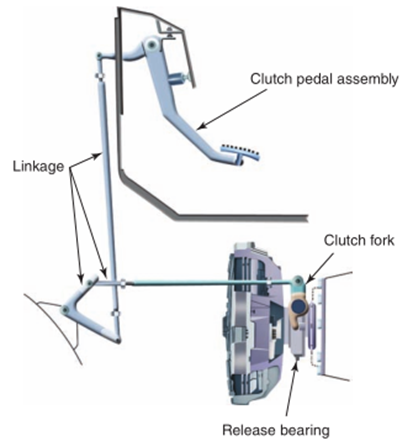

IV. Release Mechanisms: Pull Type vs. Push Type

Understanding the separation method is crucial for maintenance teams:

Push Type: The release bearing is pushed toward the engine. Mostly found in medium-duty trucks with no internal adjustment.

Pull Type: The release bearing is pulled away from the flywheel toward the transmission. This is the global standard for heavy-duty trucks like the F3000. It allows for internal adjustment and the use of a Clutch Brake.

The Critical Role of the Clutch Brake

In non-synchronized transmissions, the clutch brake is indispensable. It is a friction disc keyed to the input shaft.

- Operation: Engaging the last 1/2 to 1 inch of pedal travel stops the input shaft from rotating. This allows the driver to shift into 1st or Reverse from neutral without “gear clashing” (打齿), significantly extending transmission life.

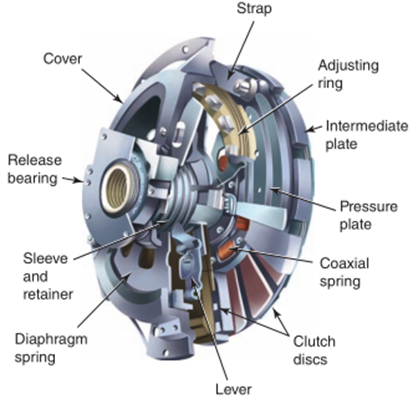

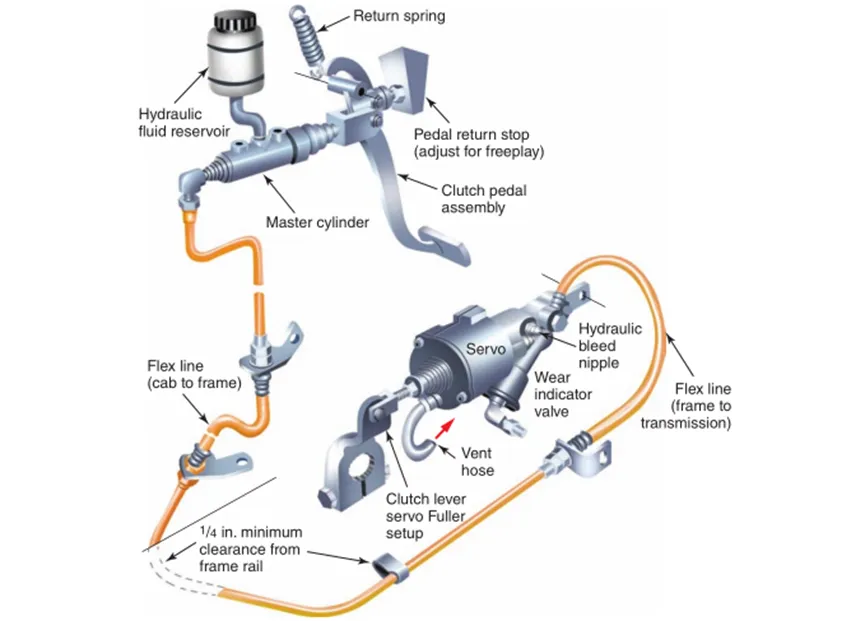

V. The AMT Revolution: Eaton DM and Two-Pedal Systems

In recent years, the rapid proliferation of Automated Manual Transmissions (AMT) in truck chassis has fundamentally changed how clutches operate. Specifically, the control has shifted from the driver’s left foot to the Electronic Control Unit (ECU).

1 .Defining the DM System: Datalink Mechanical

Eaton uses the term DM, short for “Datalink Mechanical,” to describe a mechanical clutch that is managed electronically via the vehicle’s data link.

- The Two-Pedal System: In modern two-pedal systems, there is no clutch pedal. The clutch must still be operated mechanically, but the timing and force of engagement are dictated by the ECU.

- Mechanical Integrity: Despite the electronic brain, the physical role of the clutch—transferring torque from the flywheel to the transmission—remains unchanged.

2.Centrifugal Clutch Logic in AMT

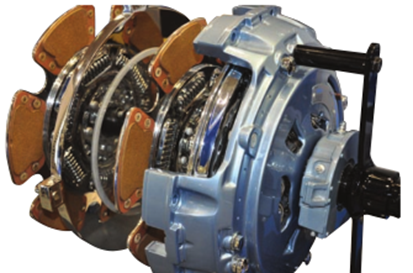

Heavy-duty centrifugal clutches, such as those introduced in the Eaton UltraShift (15.5-inch dual-disc ceramic), utilize centrifugal force generated by engine speed to achieve engagement.

- Ball-Ramp Engagement: These assemblies use a ball-ramp engagement hub that fits within a standard clutch housing.

- Inertia Brake: They often feature an integral inertia brake (acting as a clutch brake) to slow down the input shaft, allowing for significantly faster automated upshifts.

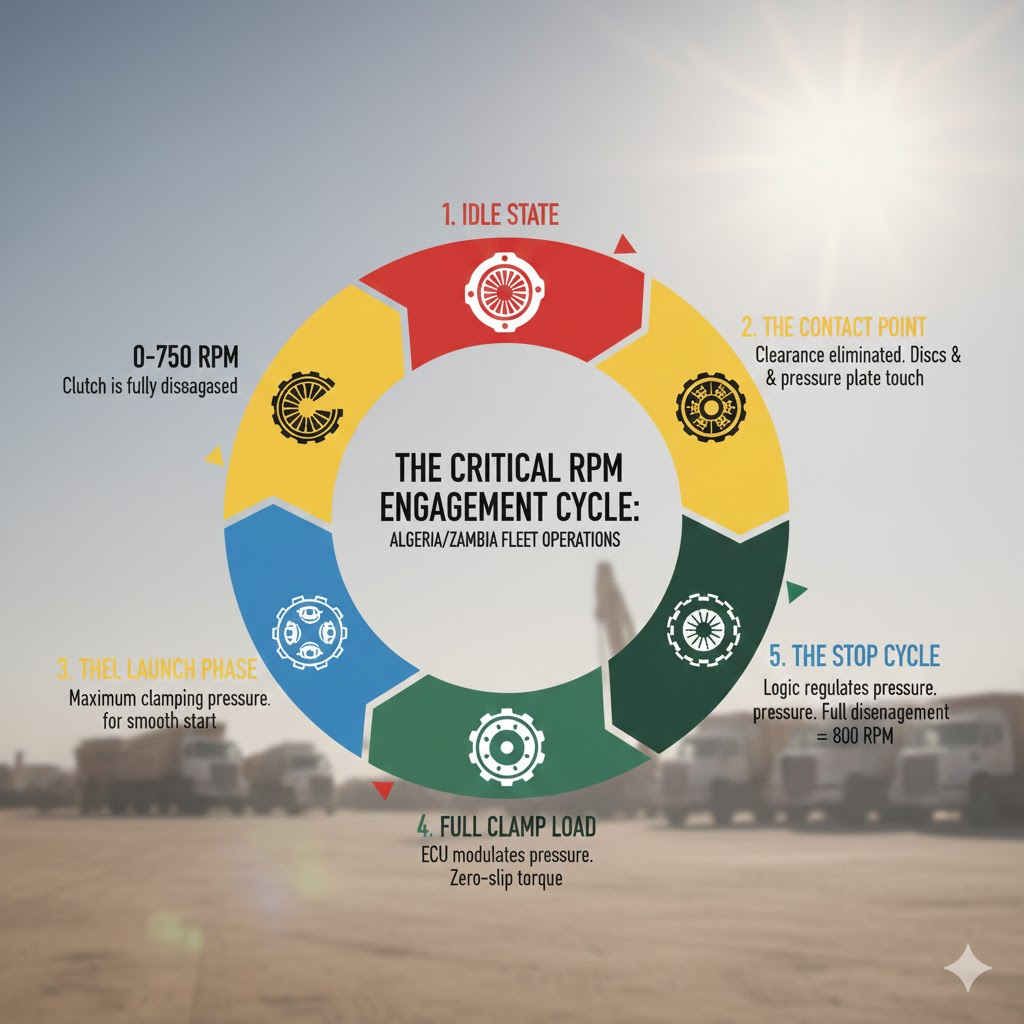

3.The Critical RPM Engagement Cycle

For fleet operators in regions like Algeria or Zambia, understanding the RPM engagement window is vital for preventing premature wear:

- Idle State: At engine idle, the clutch is fully disengaged.

- The Contact Point (750–850 RPM): As engine speed increases, the clutch reaches its “Contact Point” where the clearance between the discs and the pressure plate is eliminated.

- The Launch Phase: Between the contact point and approximately 1,350 RPM, the system is in the “launch phase.” The ECU coordinates with the engine controller to modulate RPM for a smooth start.

- Full Clamp Load (1,350 RPM+): Once the engine exceeds 1,350 RPM, the centrifugal force provides maximum clamping pressure, ensuring zero-slip torque transfer.

- The Stop Cycle: When the vehicle slows to a stop, the logic regulates clamping pressure until full disengagement occurs at approximately 800 RPM.

Strategic Market Outlook: Algeria, Zambia, and Tanzania

The massive influx of Chinese and Korean heavy machinery (SHACMAN F2000/F3000, XCMG ZL50GN, Hyundai HX series) has created a vacuum in the high-quality spare parts market.

Why Importers Should Invest in Clutch Inventory NOW:

- Rigid Demand: Every F3000 and HX340 currently sold will require at least one clutch replacement within the next 12-24 months due to extreme African operating conditions.

- The Downtime Penalty: In the mining sector (Zambia), a truck waiting 45 days for a clutch from overseas loses thousands of dollars in revenue. Local stockists own the market.

- Technical Shift: As fleets move to AMT, they require specialized DM modules and Solo (Adjustment-free) clutches. Importers who provide these high-tech components will replace traditional “commodity” part sellers.

Conclusion: Partnering for Performance

The era of “guessing” clutch maintenance is over. Successful fleet operation in 2025 and beyond requires a commitment to engineering-grade parts and a deep understanding of the transition from manual to AMT systems.

Qingdao Kailai provides the heavy-duty clutch solutions specifically engineered for the African environment. From ceramic 6-button discs for the Hyundai HX340 to the complex DM modules for SHACMAN AMT trucks, we ensure your fleet stays on the road.

Contact us to secure your strategic parts inventory and dominate the local market.

Contact: William Technical Strategy & Sales (Africa Division) Phone/WhatsApp/Wechat: +86 186 6977 8647 Email: Sales22@chinatruck.cc